We ensure our products are safe and of highest quality and good for people and the planet. Our promise extends to how and what we source, manufacture, package, and transport along with what happens when our consumers dispose products after use. We believe that having a sustainability approach makes a better product and not just a more environmentally friendly one.

To ensure we make effective use of limited resources, and minimize our impact on ecosystems, we focus on developing sustainable products with a Life Cycle Assessment (LCA) lens.

Our aim

Our progress so far

We carry out LCAs to understand the environmental impact of our products across their entire lifecycle from sourcing of raw materials right to end-of-life or disposal. The LCAs are aligned as per the standards ISO 14040:2006 (and its amendment 14040:2006/Amd 1:2020), and ISO 14044:2006 (and its amendments 14044:2006/Amd 1:2018 and 14044:2006/Amd 2:2020).

As of 2025, we have completed LCAs for 41% of our products by revenue and we aim to complete assessments for 80% of our products by revenue by 2025-26.

The findings help us determine environmental hotspots or areas of concern. These serve as the starting point for our greener product initiatives. Through the systemic cradle-to-grave approach, we reduce risks of sub-optimisation and problem-shifting from one part of the life cycle to another or from one type of impact to another. LCAs help us bring new insights about how action in one stage of the product life cycle may lead to upstream or downstream effects far away from the point of action, perhaps in vastly distant geographical locations as well.

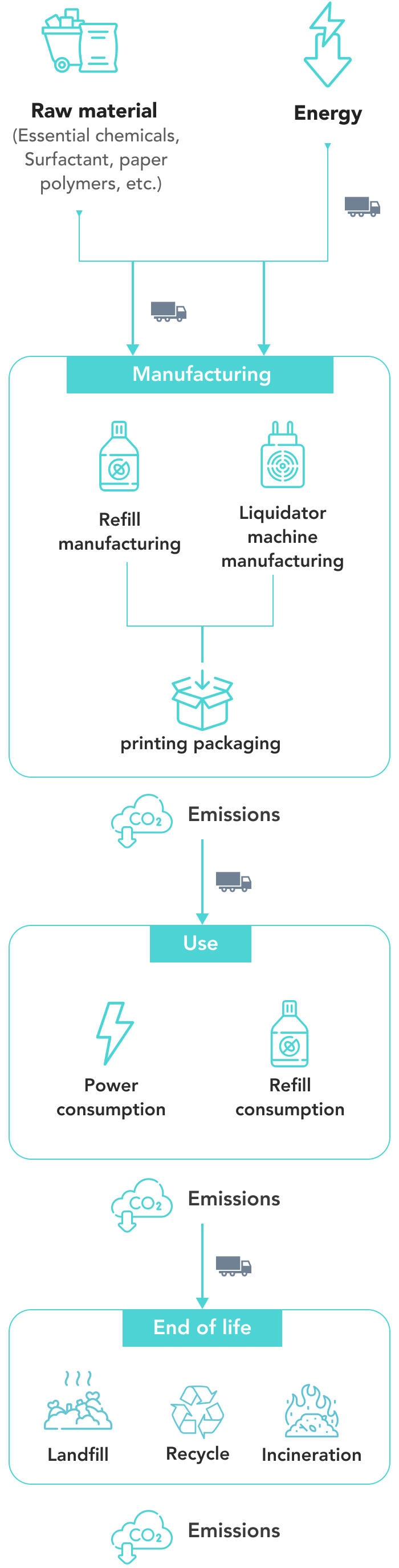

Our LCA scope covers the production phase – raw materials supply, upstream transportation, manufacturing process, use phase and end-of-life phase of our products.

Cradle to grave assessment coverage – example of Good Knight Liquid Vapouriser

Life cycle impact assessment indicators

| Indicators | Unit |

|---|---|

| Acidification terrestrial and freshwater | Mole of H+ eq. |

| Cancer human health effects | CTUh |

| Climate Change | kg CO2 eq. |

| Ecotoxicity freshwater | CTUe |

| Eutrophication freshwater | kg P eq. |

| Ozone depletion | kg CFC-11 eq. |

| Photochemical ozone formation - human health | kg NMVOC eq. |

| Resource use, energy carriers | MJ |

| Resource use, mineral and metals | kg Sb eq. |

| Water scarcity | m³ world eq. |

We define greener as products that consume lower energy and water to manufacture, they have lower emissions, they are built using greener/recycled raw materials, they use lesser plastic or have more efficient overall packaging.

Using greener raw materials

Good Knight Gold Flash is the latest liquid vapouriser from our Good Knight brand. The technology used that was used in our wicks was imported at a high cost from a monopoly vendor. In addition, the wicks were made from non-biodegradable and non-reusable material. Seeing this as an opportunity, the team started to explore and develop an indigenous wick that could deliver the need at better cost and lower environmental impact. After evaluating materials such as glass wool, carbon fibers, plant fibers and low density materials like wood dust, and silicone dust, the team narrowed on a specific grade of plant fibers that have better thickness and tensile strength than others. The new 100% biodegradable wick is our owned patented indigenous formulation. It’s not dependent on a single vendor and is feasible to manufacture inhouse in our regular clay wick vendor sites. It’s at par with the product’s efficacy and longevity. It’s 70% cheaper than the imported wick, and reduces our plastic usage by more than 300 tonnes a year.

Lower environmental impact in operations

As we channel innovation in making delightful products, we are also making them good for the planet. Our manufacturing processes and operations emit half the emission than in FY11. We use 39% less water and 35% less energy to make our products and 27% of all our energy is from renewables sources.* Across our manufacturing operations we send zero waste to landfill.

* From baseline of FY11

Innovating to lower packaging and transportation impact

We have innovated reconstitution technologies for our personal and home care product categories through the Magic product line that uses less water, less plastic packaging and reduces carbon emissions as we transport more product in less trips. Reconstitution products are gentle as they have less fillers and other additives. This range of products is innovative, sustainable, effective, and affordable. Magic Floor Cleaner is the latest from our reconstitution range. It uses 94% less plastic than traditional floor cleaners. We are also able to transport 5x more refills helping us significantly lower the emission footprint of our product.

Lowing environmental impact on use

Traditional aerosols burden the planet with metallic cans and petroleum-based solvents, but our Good Knight Mini Spray breaks the mould. It is an insecticide aerosol designed to be highly effective while reducing its impact on the environment. We have replaced LPG-based aerosols with a meter dose pump spray technology that eliminates the need for non-renewable fossil fuels and enhances the product’s sustainability. The smaller, lighter packaging also reduces fuel consumption during transportation and helps lower our emission footprint.

Taking back what we send out

Our LCAs account for end-of-life environmental impacts of our products. As a consumer products company, all of our products are consumable. However, our product packaging we send out is our responsibility. We are address this by ensuring we collect post-consumer plastic waste equivalent to 100% of plastic packaging we put in the market. Additionally, we are also looking to reduce our packaging intensity incorporate more post-consumer recycled plastic into our packaging and explore alternatives to plastic packaging.